DJ340plus

- Functional and versatile software abilities

- Multiple communication interfaces for printing external data

- Remote control and monitor

The DJ340 plus is a great alternative for advanced coding and marking on secondary packaging. It has multiple communication interfaces to expand its capabilities of data printing from external devices, database, MySQL, etc. Able to be equipped with a mini router to connect to a Wi-Fi network.

Printer’s controller screen can be remotely monitored and operated through Dotjet’s Inkjet CMD System.

|

Controller / Operation Interface The controller is designed with a WYSIWYG and user-friendly operation interface. Users can edit print templates straightforwardly and set up printing parameters quickly through clicking on the 7” full-color touch screen directly. |

|

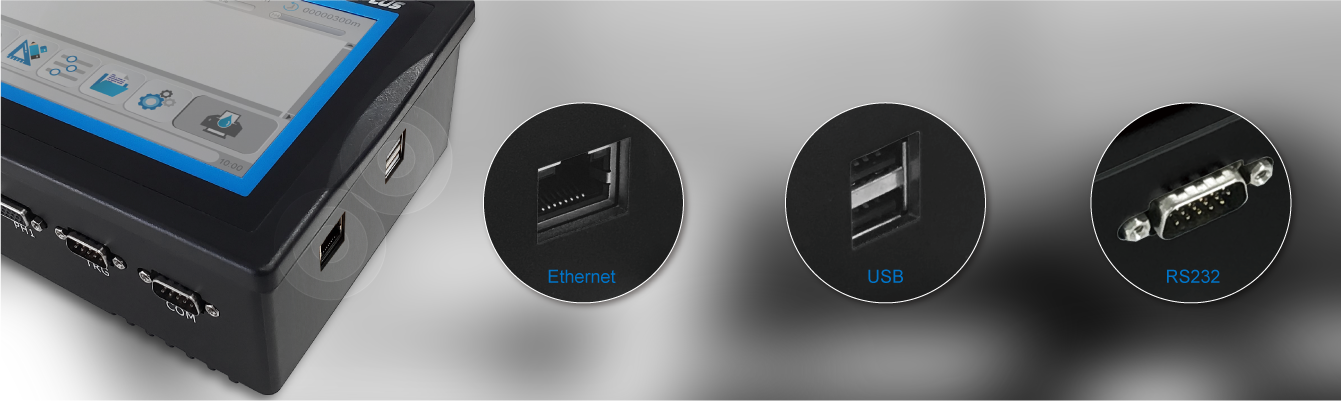

Communication Interface

The DJ340plus has multiple communication interfaces, including USB, TCP/ IP, RS232, emphasizing the capability of advanced application for coding and marking.

Are advanced applications complicated? What if your customer asks for an application that seems a customized function? Dotjet team gives distributors full support and simplifies the process to help distributors and users resolve the problem. Let Dotjet team assist you achieve missions beyond basic coding and marking.

- Communication Interfaces: MySQL, SQLite(.db3, .sqlite), Database (.csv), RS-232, MQTT, TCP/IP, and Dotjet Protocols

- Able to be equipped with a mini router to connect to a Wi-Fi network.

|

Software

|

|

Remote Control and management

Dotjet DJ340plus software is available for remote print control and management functions designed to streamline operations and increase productivity. The Dotjet Cloud integration allows users to remotely access and monitor the DJ340plus printer from any location. This allows real-time oversight of printing operations, including checking print status, ink levels and printer performance.

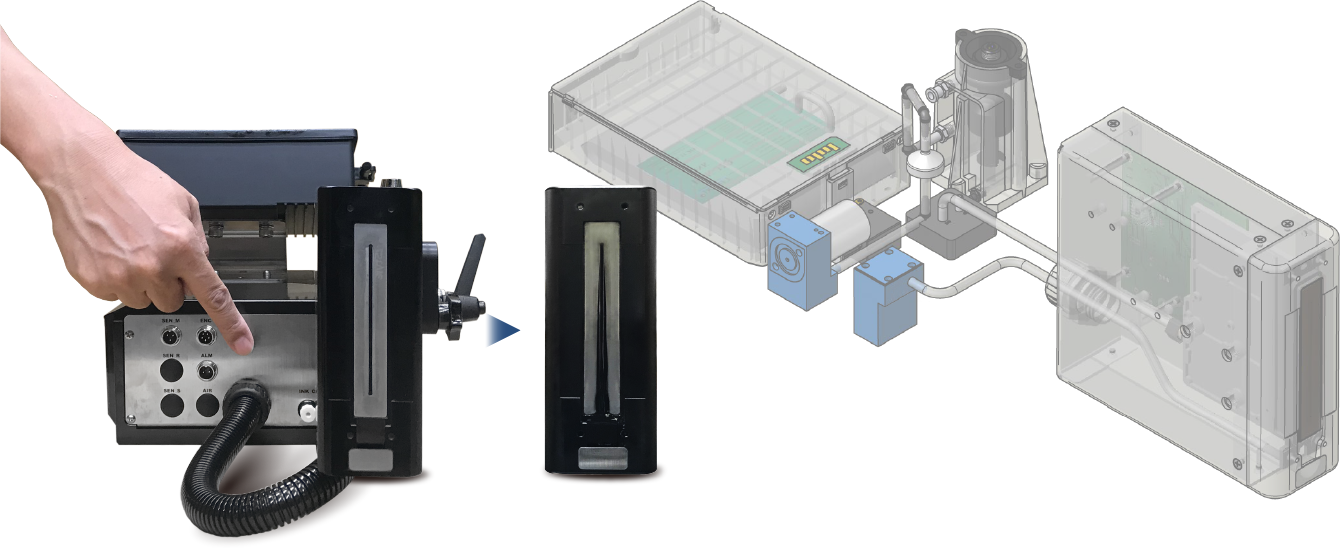

Pumping Ink Delivery

The integrated ink pump and auxiliary ink tank maintain the required pressure in the system to ensure a stable and reliable supply of ink to the printhead and perform automatic ink delivery management. A high-efficiency filter prevents any contaminants from entering the printhead, thus prolonging the life of the printhead and maintaining print quality.

As a Windows-Compatible Printer

The printer seamlessly integrates with popular Windows applications, allowing direct printing of files from software output.

Superior Printing Technology

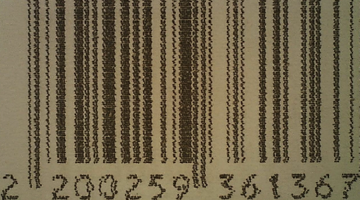

Although manufacturers of piezo inkjet printers use the same print engine, Dotjet's technology ensures precise control over the position of the ink droplets, resulting in smoother gradations, finer lines and less graininess. This precision is essential for high quality printing, especially for fine barcode printing, and the DJ340plus ensures a high level of barcode printing.

|

Printing effect of other brands |

Dotjet’s technology |

| Specifications | |

|---|---|

|

Technology |

SPT Piezoelectric technology |

| Power supply | AC110-220V, 50/60HZ |

| Display | 7” Color LCD with LED backlight |

| Operating temperature range | 5°C-45°C (41°F-113°F) |

| Message storage | Up to 1000 messages |

| Maximum print height | 18mm for PT128 head; 72mm for PT510 head |

| Print lines | Multiple lines depanding upon the print character size |

| Message length | Maximum to 1024mm |

| Print resolution | 180 dpi |

| Printing orientation | Horizontal and vertical printing |

| Distance to print Surface | Maximum 6.5mm (0.25 inches) |

| Print speed |

98 feet/min (30m/minute) at 180dpi with 18mm print head. |

| Print capability |

Alphanumeric of full true type fonts. Scalable text; rotation, mirror and inverse printing. Automatic time and date functions. Automatic best-before date calculation. Automatic incrementing & decrementing batch counting and Lot-Box code. Auto repeat printing. Graphic format supported using 1 bit bitmap file. (*.bmp) 16 programming shift codes with automatic rollover. GS1 barcodes / 2D codes. External data connectivity print. Database print. |

| Database print format | CSV |

| External data communication interface | USB, Ethernet, TCP/IP, RS232 |

| Particular features | MySQL database, Print data collection, Protocol control,Image in database, Multiple printer remote control by Dotjet inkjet CMD software |

| Ink usage | Oil and UV curing inks |

| Ink supply | 250ml ink cartridge. 500ml bulk ink supply is optional |

| Dimension (L/W/H) |

Controller 345 x 260 x 76 mm / 13.4 x 10.2 x 3 inches Print head & Ink delivery system 160 x 450 x 140 mm / 6.3 x 17.7 x 5.5 inches |

| Optional | Encoder, bulk ink supply, External low ink alarm, Dotjet inkjet CMD software |